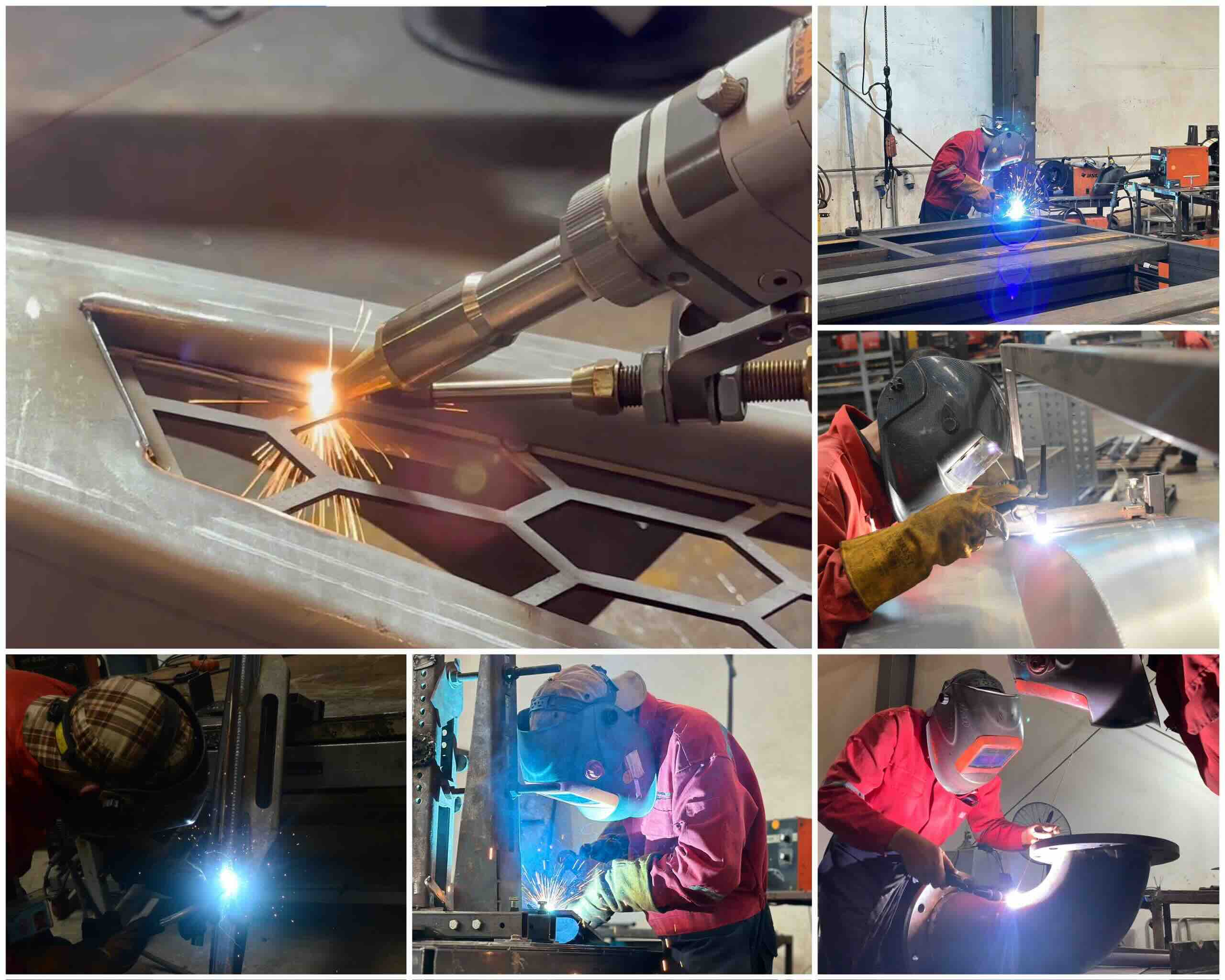

High-Quality Welding Services in Vietnam

No matter what your welding requirements are, the team here at Australian General Engineering Vietnam can achieve it for you. Your quality can be committed with ISO 3834-2 certification for our welding processes which is an internationally recognized welding quality management system standard.

Our qualified welders are highly experienced and can cater for applications from prototypes through to automated robotic volume production. These processes are supported by a range of MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), stud, spot, and projection welding machines suitable for a wide variety of welding applications.

Using Only The Best For Our Quality Welding

Australian General Engineering Vietnam team understands the importance of meeting our client's needs and strives to deliver high-quality products and services that exceed their expectations.

We have fully equipped MIG and TIG welding bays for the skilled welding of mild steels, stainless steels, and aluminium components. We manufacture our own dedicated jigs and fixtures in-house to assist with maintaining accuracy, quality, and speed during our welding process. At our Vietnamese facilities, our welding teams can conduct all types of welding procedures on all metal surfaces.

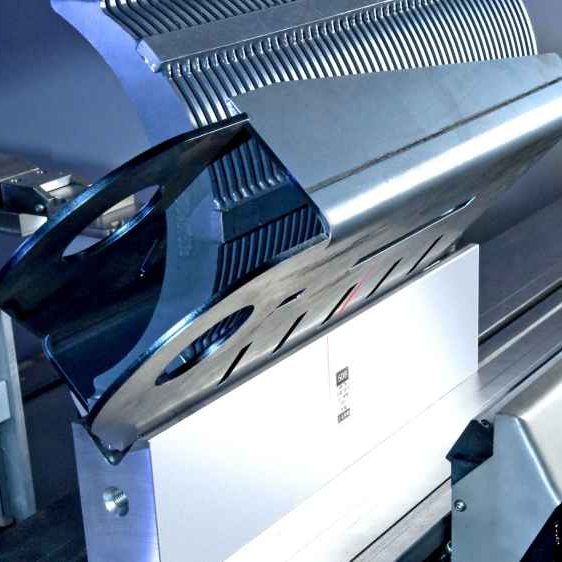

Additionally, we have equipped laser welding machines in our process. Utilizing laser welding for sheet metal enables significant welding speeds, simplifies the process, and delivers superior, uniform results across materials and thicknesses compared to traditional MIG or TIG methods. It minimizes the heat-affected zone and reduces the necessity for conventional post-weld processing such as grinding or polishing, leading to enhanced productivity, reduced scrap, and lower per-part costs.

This is just another added in-house service that we offer to our customers to ensure your parts function correctly and are aesthetically pleasing. Metal polishing and dressing services are also provided to enhance the final finish of your components when required.

Our High Quality Manufacturing Services

Our welding team is an important part of the leading metal manufacturing services we offer at our Vietnamese facility. These also include:

- CNC laser cutting

- Turret punching

- Tube bending

- Folding, pressing and stamping

- CNC machining

This complements our range of value-added services, such as providing sub-assemblies, kanban or direct to line, and other specialist fabrication processes.

BRAKE PRESSING / FOLDING

Fast and accurate brake pressing/folding of a range of metals is facilitated with our sophisticated CNC brake press machinery. Through easy to set up and operate methodology, we can quickly tum out precision workmanship that aids the smooth and timely fabrication of our clients' components.

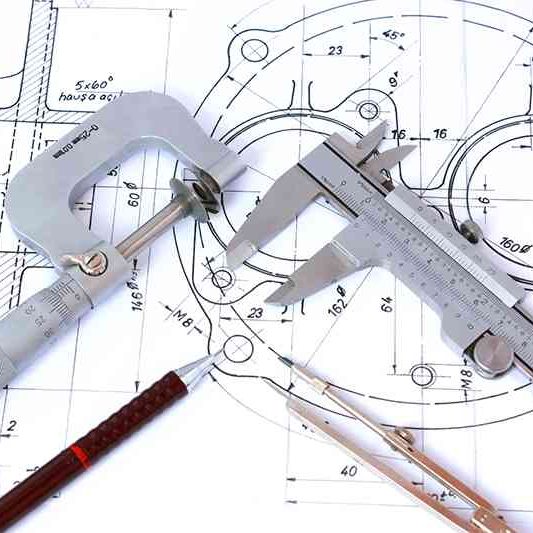

DESIGN CAD & CAM

If you require design and prototyping services for your metal part, our skilled team of industrial designers is ready to fulfill exactly what you need. With expertise in CAD/CAM design using Inventor and Solid Works software, we can provide you with highly realistic rendered images to showcase your products effectively.

AUTOMOTIVE DIAGNOSTIC TROLLEY/TOOL STORAGE

This trolley is designed for diagnose errors in automotive factory or garage. It has space for diagnostic tool on top which can fit to various sizes of PC/laptop. Additionally, this has 4 drawers and 1 room in the bottom to store for multiple diagnostics and repairing tools.

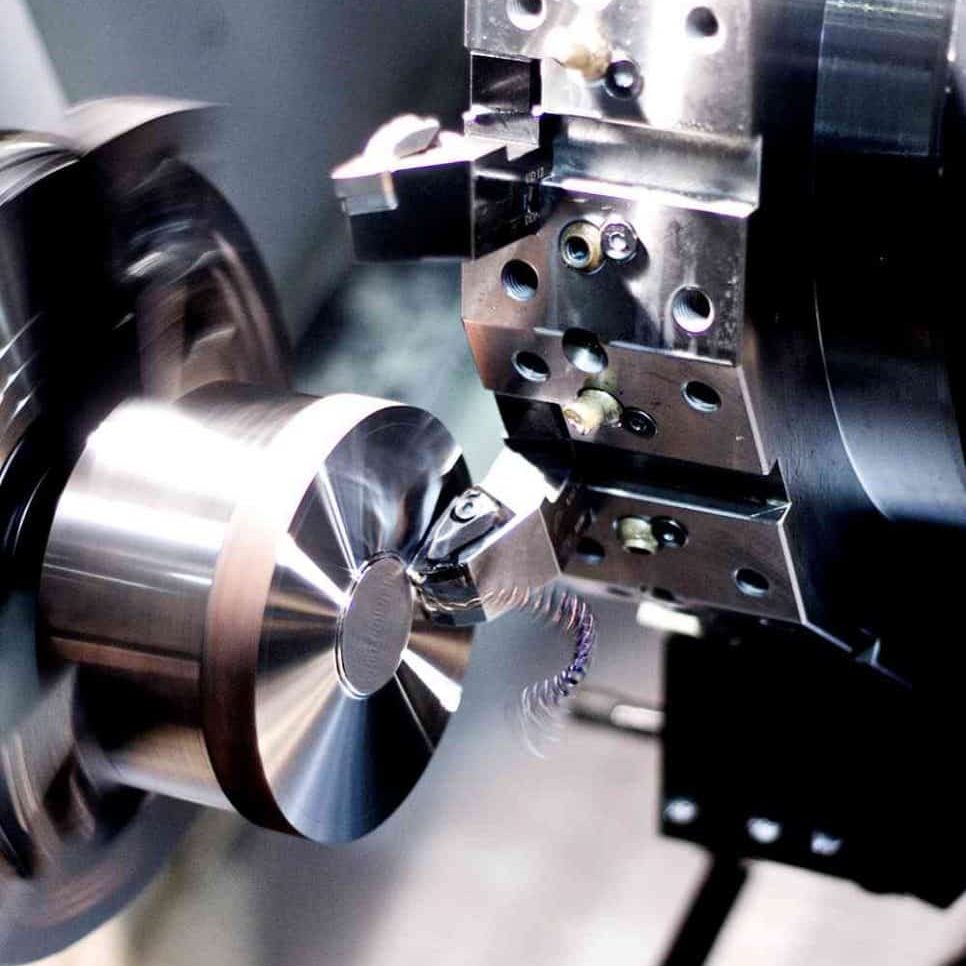

CNC MACHINING

If your products require accurate and efficient turning or milling, you need our highly professional CNC machining services. Every step of our CNC machining processes is audited for quality and accuracy.